UST Mamiya ATTAS5 GoGo Driver Shaft

The UST ATTAS5 is the late 2013 addition the the ATTAS family of shafts. It compliment the ATTAS3 and ATTAS4u reviewed earlier. The ATTAS shafts are ultra premium models made from ultra-high modulus, low resin content materials. They are available from UST Mamiya Tour SPX certified fitters only.

The UST ATTAS5 is the late 2013 addition the the ATTAS family of shafts. It compliment the ATTAS3 and ATTAS4u reviewed earlier. The ATTAS shafts are ultra premium models made from ultra-high modulus, low resin content materials. They are available from UST Mamiya Tour SPX certified fitters only.

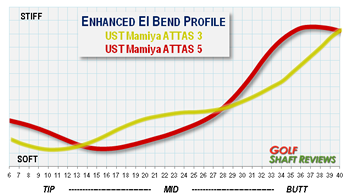

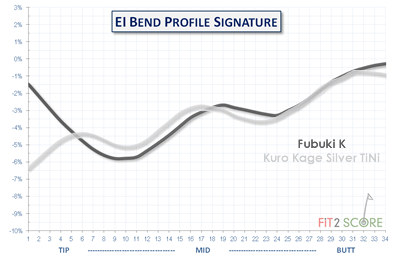

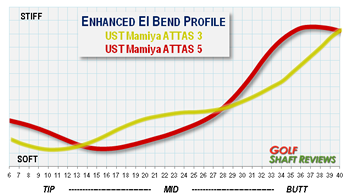

I see in the ATTAS 5 a design that keeps showing up in new shaft releases. A steeply descending profile showing a rapid loss of stiffness from butt to tip, with a long stiff tip. The difference between one brand and the next is the rate of stiffness lost and the length of the tip section of the driver shaft. The new ATTAS 5 and the ATTAS 3 released a few years ago are a good high launch vs low launch pair. The 6 Stiff profiles are compared in this illustration. The ATTAS 5 is softer in the mid section. It will create good launch and spin for a golfer with a flat to negative angle of attack. The stiff mid ATTAS 3, fitting the player with a positive angle of attack, looking to create a lower spin penetrating ball flight. The ATTAS 5 design is a good compliment to the low launch, low spin heads and balls that are common in the 2013-2014 marketplace.

I see in the ATTAS 5 a design that keeps showing up in new shaft releases. A steeply descending profile showing a rapid loss of stiffness from butt to tip, with a long stiff tip. The difference between one brand and the next is the rate of stiffness lost and the length of the tip section of the driver shaft. The new ATTAS 5 and the ATTAS 3 released a few years ago are a good high launch vs low launch pair. The 6 Stiff profiles are compared in this illustration. The ATTAS 5 is softer in the mid section. It will create good launch and spin for a golfer with a flat to negative angle of attack. The stiff mid ATTAS 3, fitting the player with a positive angle of attack, looking to create a lower spin penetrating ball flight. The ATTAS 5 design is a good compliment to the low launch, low spin heads and balls that are common in the 2013-2014 marketplace.

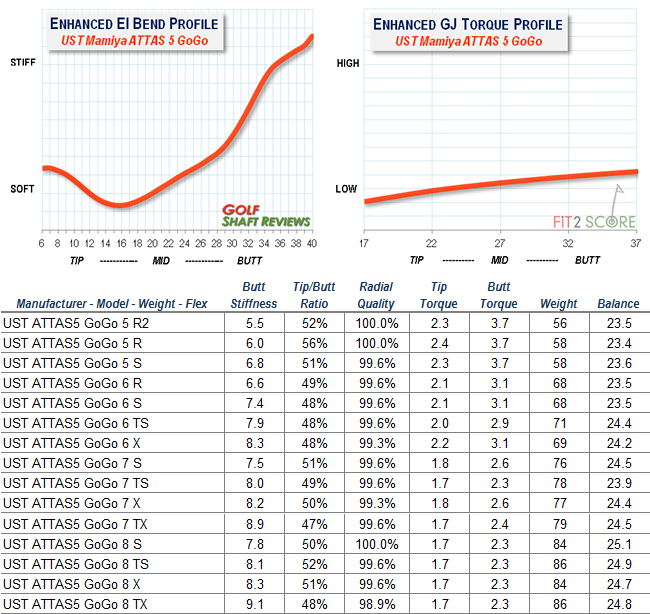

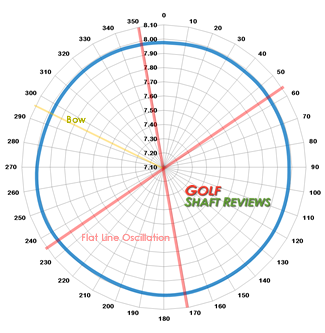

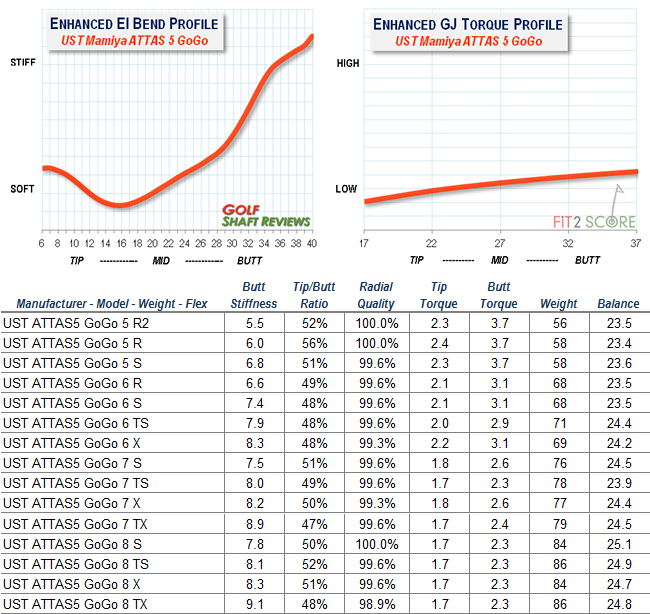

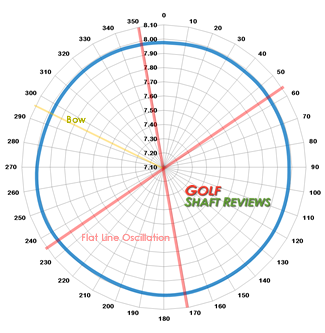

What struck me as I measured the ATTAS 5 GoGo review samples was the radial quality. Several of the shafts had perfect radial quality measurements. So perfect in fact that they showed very little change in oscillation patterns in any orientation. That prompted me to take a hard look at the 8 stiff shaft. The red lines in this illustration show the Flat Line Oscillation (FLO) planes. These indicate the high and low points of stiffness around the shaft. On a perfect shaft such as this, they did not fall 90 degrees apart as is typical. The Bow plane of the shaft was not a point as shown on the graphic, but rather a 50 degree range, centered at the spot shown, that indicates a shaft which is not only perfectly round, but also perfectly straight. Shafts such as this show us what is possible with current production technology if you are willing to spend $605. If you have a rotating hosel the ATTAS 5 GoGo shafts can be orientated in any direction with no regard whatsoever for alignment.

What struck me as I measured the ATTAS 5 GoGo review samples was the radial quality. Several of the shafts had perfect radial quality measurements. So perfect in fact that they showed very little change in oscillation patterns in any orientation. That prompted me to take a hard look at the 8 stiff shaft. The red lines in this illustration show the Flat Line Oscillation (FLO) planes. These indicate the high and low points of stiffness around the shaft. On a perfect shaft such as this, they did not fall 90 degrees apart as is typical. The Bow plane of the shaft was not a point as shown on the graphic, but rather a 50 degree range, centered at the spot shown, that indicates a shaft which is not only perfectly round, but also perfectly straight. Shafts such as this show us what is possible with current production technology if you are willing to spend $605. If you have a rotating hosel the ATTAS 5 GoGo shafts can be orientated in any direction with no regard whatsoever for alignment.

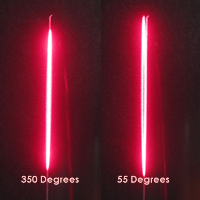

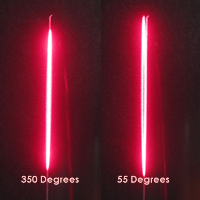

If you are not a club builder you may not be familiar with the term FLO. It is located by clamping the butt of the shaft and attaching a weighted laser pointer to the tip. These images are a 5 second time delay photo of the laser tip oscillating. As you can see, the oscillation follows the stripe on the board perfectly in both planes. This simple technique quickly finds the hard and soft planes of a golf shaft.

If you are not a club builder you may not be familiar with the term FLO. It is located by clamping the butt of the shaft and attaching a weighted laser pointer to the tip. These images are a 5 second time delay photo of the laser tip oscillating. As you can see, the oscillation follows the stripe on the board perfectly in both planes. This simple technique quickly finds the hard and soft planes of a golf shaft.

The clamping device is a laser detection instrument that measures the oscillation rate of the shaft. This is called the frequency of the shaft. It is a method of measuring stiffness.  Frequency matched shaft sets are made using this equipment. By comparing the frequency of the two FLO planes, the radial consistency of the shaft is quickly determined. If the frequency on the two FLO planes are the same, or nearly the same, the shaft is perfectly round. The UST Mamiya ATTAS 5 shafts are perfectly round.

Frequency matched shaft sets are made using this equipment. By comparing the frequency of the two FLO planes, the radial consistency of the shaft is quickly determined. If the frequency on the two FLO planes are the same, or nearly the same, the shaft is perfectly round. The UST Mamiya ATTAS 5 shafts are perfectly round.

This photo shows the clamp with a radial protractor attached to the shaft. The tip points to a board with a vertical line, That line guides the deflection perpendicular to the clamp. Suspended above the shaft is the camera used to take the photos and video for this short demonstration of shaft oscilliation

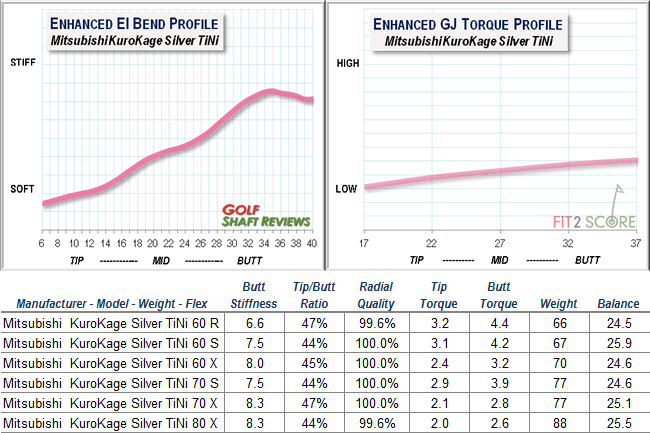

![]() Fujikura tells us the Ventus driver shaft is made with full length Pitch 70 Ton Carbon Fiber material that is 150% stronger than Toray T1100g. T1100g is used in many premium driver shafts. In the Ventus,the 70 ton full length fiber is combined with 40 Ton Carbon Fiber to minimizes twisting. We here from them that high torque creates dispersion. The design of the Ventus is low tip torque to decrease dispersion. Years of fitting experience validate this torque observation. The stock shafts in most drivers have higher torque than the shaft upgrades offered by both the club companies and aftermarket fitters.

Fujikura tells us the Ventus driver shaft is made with full length Pitch 70 Ton Carbon Fiber material that is 150% stronger than Toray T1100g. T1100g is used in many premium driver shafts. In the Ventus,the 70 ton full length fiber is combined with 40 Ton Carbon Fiber to minimizes twisting. We here from them that high torque creates dispersion. The design of the Ventus is low tip torque to decrease dispersion. Years of fitting experience validate this torque observation. The stock shafts in most drivers have higher torque than the shaft upgrades offered by both the club companies and aftermarket fitters.