ACCRA TOUR Z DRIVER SHAFTS

ACCRA started in 2002 as a Canadian distributor for Royal Precision and UST. In 2004 they started into the shaft business licensing the ACCRA brand name from UST. In 2007, they purchased the brand name and embarked on independent development of premium golf shafts distributed exclusively through certified ACCRA fitters.

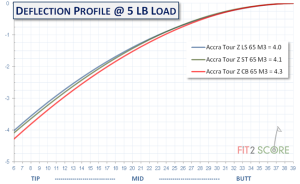

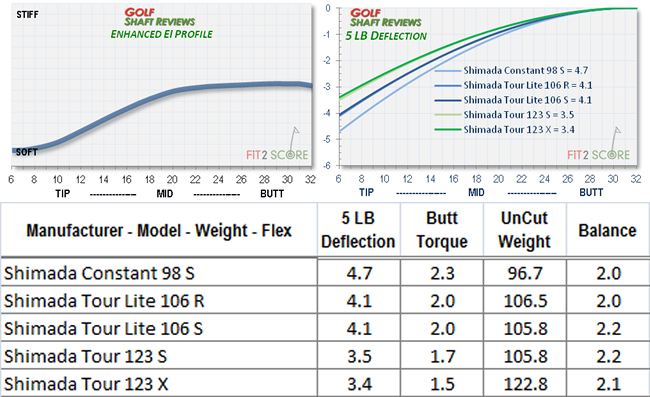

The ACCRA Tour Z is available in three launch designs; ST (stable tip) low launch, CB (counter balance) low mid launch and LS (low sping) mid launch. The Tour Z has an iridescent logo that changes color in the sunlight as the shaft is rotated. The weight and flex are noted near the tip. The raw shafts are market with the stiff and weak planes facilitating alignment for those inclined to do so. Our testing has shown excellent radial consistency, the ACCRA Tour Z is suitable for use in rotating hosels without regard for alignment.

The ACCRA Tour Z is available in three launch designs; ST (stable tip) low launch, CB (counter balance) low mid launch and LS (low sping) mid launch. The Tour Z has an iridescent logo that changes color in the sunlight as the shaft is rotated. The weight and flex are noted near the tip. The raw shafts are market with the stiff and weak planes facilitating alignment for those inclined to do so. Our testing has shown excellent radial consistency, the ACCRA Tour Z is suitable for use in rotating hosels without regard for alignment.

I had a chance to talk to Gawain Robertson, co owner of ACCRA Golf, at the 2014 PGA Merchandise show about club fitting and ACCRA golf shafts.

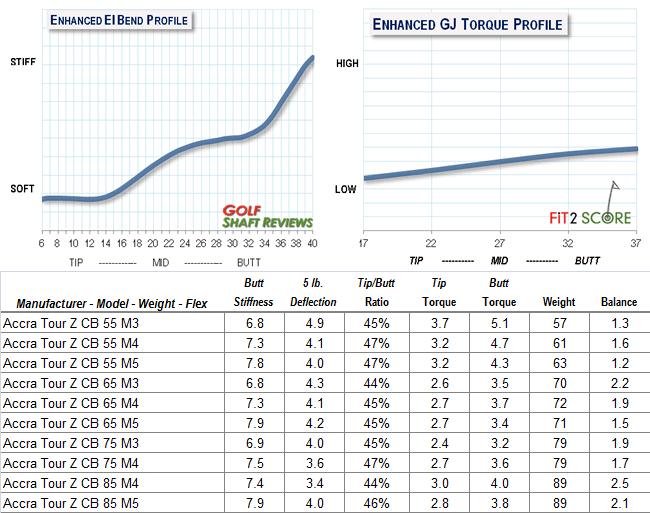

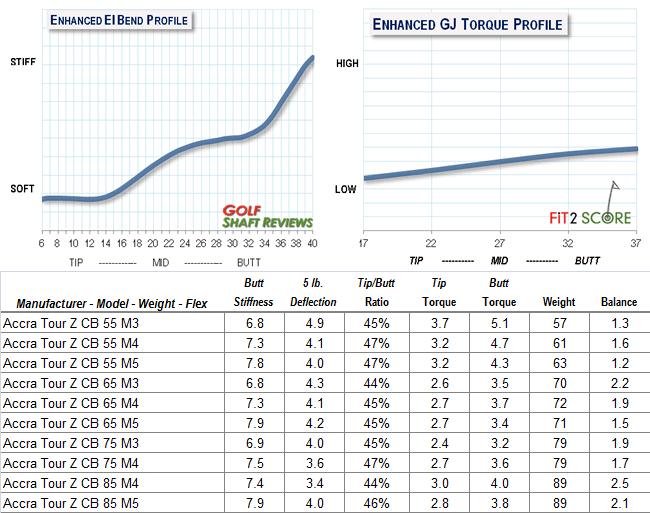

ACCRA Tour Z CB Driver Shaft

The ACCRA Tour Z CB driver shaft is the latest addition to the Tour Z brand. Although it says “CB” in it’s name, this shaft is really not counter balanced. What ACCRA has done is raised the center of gravity (CG) to offer golfers a different “feel” and launch condition from their popular ST series.

The Tour Z CB series of shafts was patterned after the extremely popular ACCRA XE and XC lines of shafts using updated materials and new design concepts.

The tip section in this shaft is slightly softer that the Tour Z ST and the torque is lower combined with the higher CG it promotes a ball flight that is only slightly higher than the ST (Mid) a spin rate that would be considered mid to low.

As with all Tour Z shafts, the CB offers Constant Flex Technology, ACCRA’s super Thin Wall design and the platinum band around the cool matte black finish certainly makes this shaft distinctive. What really makes this shaft stand out is the unique feel that is created by the combination of many technologies in one shaft.

Radial consistency was 99.5% with a .3% standard deviation. It does not get much better than that. The ACCRA tour Z shafts FLO planes are marked on the butts. You can ignore them, these shafts are good to play in any orientation.

Radial consistency was 99.5% with a .3% standard deviation. It does not get much better than that. The ACCRA tour Z shafts FLO planes are marked on the butts. You can ignore them, these shafts are good to play in any orientation.

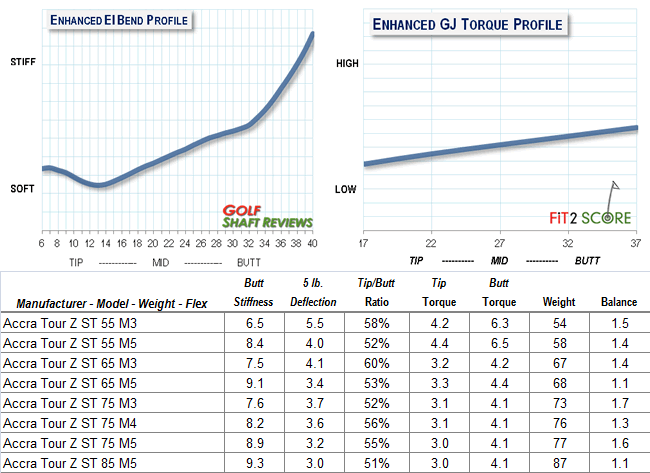

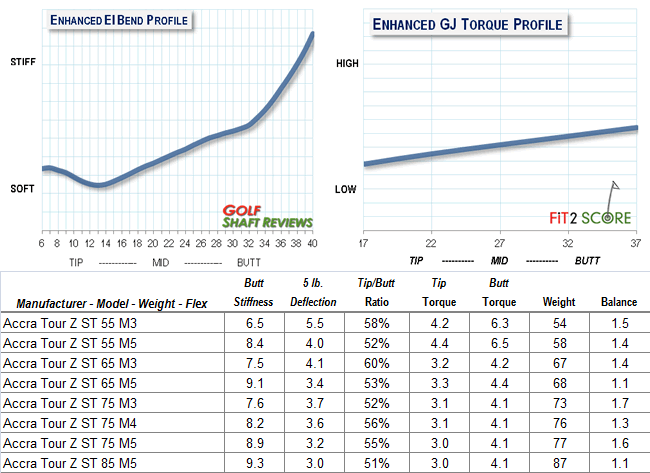

ACCRA Tour Z ST Driver Shaft

ACCRA’s first introduction in the Tour Z line was originally named Tour Z+, with the introduction of the CB and LS lines it was renamed ST in 2013. This shaft was originally designed for a specific PGA Tour player who was looking for a very stable shaft from top to bottom but still wanted “feel”. ACCRA’s engineers tested many combinations to accomplish this the final design features a super thin wall design, something that has been incorporated in all ACCRA Tour Z shafts. The super high modulus materials enabled ACCRA engineers to use these thin wall structures that enhance energy transfer and feel to the golfer yet maintains strength and durability.

From a playability stand point, this shaft certainly accomplishes what it advertises. The ST is Accra’s must popular shaft on tour with many players using the Tour Z ST 55 shaft as the stability of this shaft gives them the confidence of a heavier shaft in a 55 gram product that helps them generate more speed, without sacrificing control.

Once again, radial consistency was 99.2% with a .3% standard deviation. It does not get much better than that.

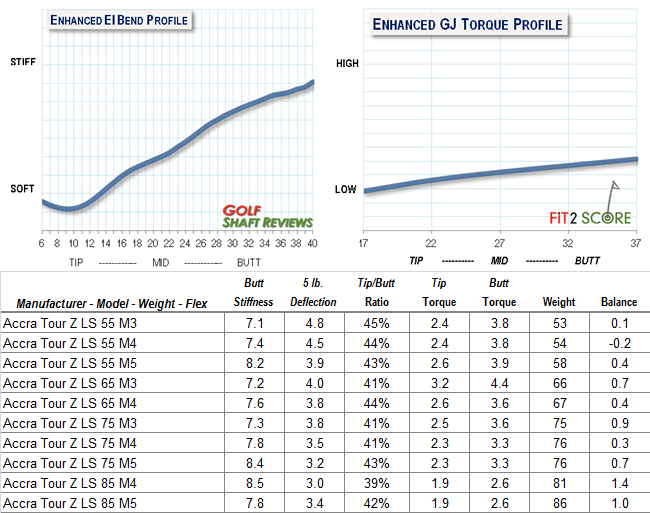

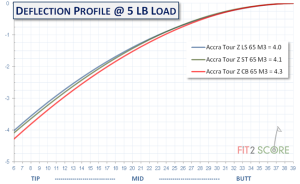

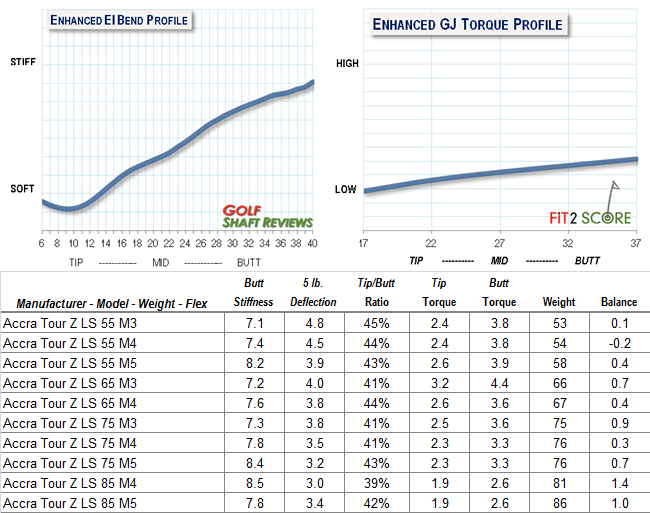

ACCRA Tour Z LS Driver Shaft

The ACCRA Tour Z LS series of shafts was originally patterned after the shaft that brought ACCRA to prominence in the premium golf shaft market. The ACCRA SE and SC series of shafts each featured a responsive tip section combined with very low torque. This was revolutionary 10 years ago.

The Tour Z LS takes that philosophy and uses the latest in design and manufacturing techniques to produce and updated version of these classic ACCRA shafts. The first thing that a golfer feels with this shaft is the responsiveness (or kick) in the tip section, this is followed by the realization that this shaft offers tremendous stability from torsional strength in the tip section.

As with all ACCRA Tour Z shafts, the LS features Constant Flex Technology and the Super Thin Wall design, enabling professional Club Fitters to perfectly fit a golfer to flex, weight, ball flight and feel. This shaft has become popular for many levels of golfers as a fairway shaft and has also become and excellent option for golfers looking for a mid-high launch/low spin option.

Radial consistency was 99.3% with a .7% standard deviation, outstanding.

The Tour Z family offers many options for all different types of swings, as with any shaft, getting fit for them by a top fitter is critical to getting the maximum performance for them.

The Highlands Performance Golf Center, Carrollton Texas

The Highlands Performance Golf Center, Carrollton Texas

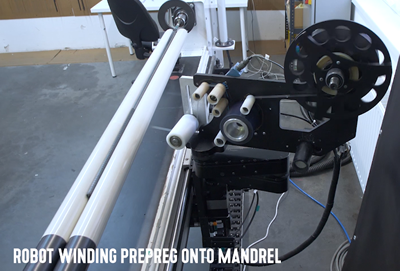

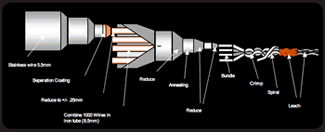

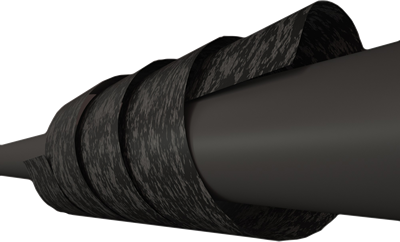

TPT makes their shafts out of carbon fiber ribbon cut from the prepreg sheets they make. The ribbon is wrapped around the shaft mandrel. The result is a seamless shaft with uniform stiffness in all orientations. That was verified in my measurement, Radial Quality, shown below. It is the best in the business.

TPT makes their shafts out of carbon fiber ribbon cut from the prepreg sheets they make. The ribbon is wrapped around the shaft mandrel. The result is a seamless shaft with uniform stiffness in all orientations. That was verified in my measurement, Radial Quality, shown below. It is the best in the business.