Wedge Golf Shafts – KBS Tour, KBS Hi-Rev, KBS CTaper, KBS Tour V

Golf wedge shafts, unlike driver shafts, do not get updated every year. When some prototypes arrived recently I realized I had not looked at wedge profiles in several years. Nothing had changed during that time. This year, the KBS Tour V and the Modus3 Tour 130 brought an entirely new profile to iron shafts. This profile is very interesting as a stand alone wedge shaft. Before we get to it, lets look at the KBS golf wedge shafts.

The KBS Tour was the first shaft introduced by Kim Braly. The wedge shaft from that model is offered as a stand alone wedge shaft. It is a mid high launch design. The KBS tour is available in 5 weights, R, R+, S, S+ and X. starting at 110 grams and ascending in 5 gram increments. When the new groove rule was introduced, Kim introduced the KBS Hi-Rev wedge shaft to get back some of the spin lost from the softening of the wedge edges.

The KBS Tour C Taper came next. It is modeled on the Project X which Kim Braly designed at Royal Precision. It is stepless and is designed to create a lower launch lower spin ball flight. While not offered as a stand alone wedge shaft product, the wedge shaft in the sets is a great choice for someone looking to lower wedge ball flight. Like the KBS Tour, the KBS Tour C Taper is available in 5 weights.

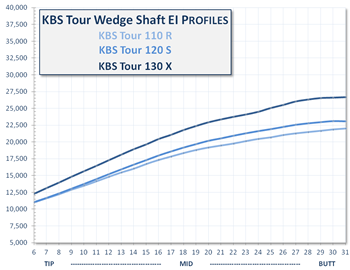

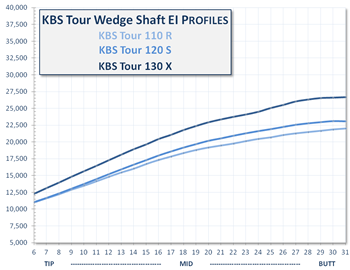

KBS Tour shafts have consistent bend profiles from flex to flex. The R is the same design as the S, just a little heavier and a little stiffer. With 5 flex/weight combinations, I fine tune flight and feel by moving up or down between weights. This illustration shows the KBS Tour wedge stiffness progressions. The same relationships are true for all KBS iron golf shafts. The KBS Tour 90 is a lighter weight version of the KBS Tour, adding two more weight options. Likewise, the KBS Tour C Taper Lite adds 3 additional weigh options to the C Taper design.

KBS Tour shafts have consistent bend profiles from flex to flex. The R is the same design as the S, just a little heavier and a little stiffer. With 5 flex/weight combinations, I fine tune flight and feel by moving up or down between weights. This illustration shows the KBS Tour wedge stiffness progressions. The same relationships are true for all KBS iron golf shafts. The KBS Tour 90 is a lighter weight version of the KBS Tour, adding two more weight options. Likewise, the KBS Tour C Taper Lite adds 3 additional weigh options to the C Taper design.

Many years ago I learned in Royal Precision Rifle Shaft Certification class how to create the Rifle Spinner Wedge Shaft. The formula was simple, go up a flex and use the 8 iron. The Rifle Golf Shaft has a parallel tip, designed to be trimmed by the club maker. I now use constant weight taper shafts exclusively. But, that lesson prompted me to look at closely at the design of the KBS Tour Hi-Rev Wedge shaft when it was introduced. And I found the designer of the Rifle product, Kim Braly, used the same principle in constant weight shafts. Knowing this, I have built countless ‘Spinner’ wedges in sets applying the same principle with all of the KBS shafts, C Tapers and C Taper Lite’s included. The feedback from my customers is universal, they love the feel of the wedge shafts on partial shots.

Many years ago I learned in Royal Precision Rifle Shaft Certification class how to create the Rifle Spinner Wedge Shaft. The formula was simple, go up a flex and use the 8 iron. The Rifle Golf Shaft has a parallel tip, designed to be trimmed by the club maker. I now use constant weight taper shafts exclusively. But, that lesson prompted me to look at closely at the design of the KBS Tour Hi-Rev Wedge shaft when it was introduced. And I found the designer of the Rifle product, Kim Braly, used the same principle in constant weight shafts. Knowing this, I have built countless ‘Spinner’ wedges in sets applying the same principle with all of the KBS shafts, C Tapers and C Taper Lite’s included. The feedback from my customers is universal, they love the feel of the wedge shafts on partial shots.

KBS Tour V Wedge Shaft

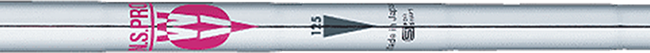

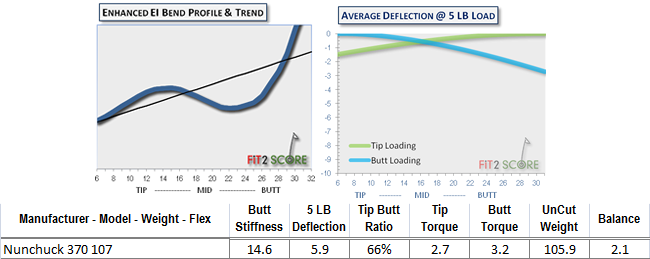

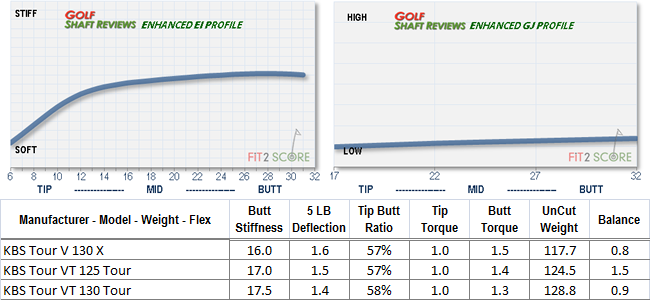

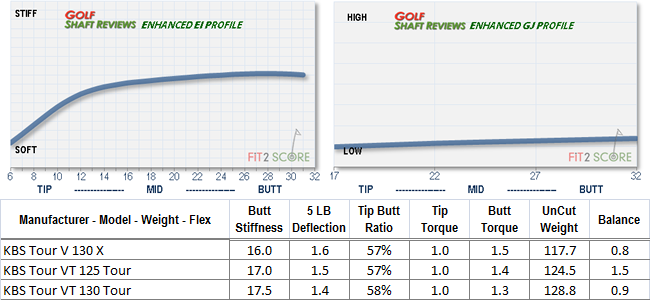

In 2014 the KBS Tour V design was introduced. The KBS Tour V is available in three weights, 110, 115 120. There are also two professional club maker, only KBS Tour V Tour weight/flex models, 125 and 130 grams. This chart shows the 130 gram V X flex and the two Tour flex models. This is a unique design. When Mark Maness tested the Tour V design his immediate reaction was to change his release because he did not like the height of the ball flight. The Tour V design is a high launch, high spin shaft. It promotes a drop and stop ball flight. That makes it an interesting wedge shaft choice.

In 2014 the KBS Tour V design was introduced. The KBS Tour V is available in three weights, 110, 115 120. There are also two professional club maker, only KBS Tour V Tour weight/flex models, 125 and 130 grams. This chart shows the 130 gram V X flex and the two Tour flex models. This is a unique design. When Mark Maness tested the Tour V design his immediate reaction was to change his release because he did not like the height of the ball flight. The Tour V design is a high launch, high spin shaft. It promotes a drop and stop ball flight. That makes it an interesting wedge shaft choice.

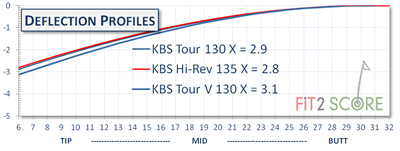

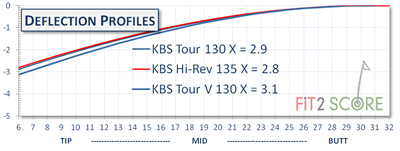

Here is a look at the deflection profiles derived from the EI profiles of the KBS Tour, KBS Hi-Rev and the KBS Tour V wedge shafts of similar weight and flex. There is not a lot of difference between the KBS Tour and the KBS Hi-Rev. But, the Tour V deflects significantly more. Based on our experience, the KBS Tour V creates a higher flight. With higher flight come more spin. That combination creates the drop and stop shot we look for from our wedges. If you are looking to add trajectory and spin to your wedges, the KBS Tour V shaft will deliver.

Here is a look at the deflection profiles derived from the EI profiles of the KBS Tour, KBS Hi-Rev and the KBS Tour V wedge shafts of similar weight and flex. There is not a lot of difference between the KBS Tour and the KBS Hi-Rev. But, the Tour V deflects significantly more. Based on our experience, the KBS Tour V creates a higher flight. With higher flight come more spin. That combination creates the drop and stop shot we look for from our wedges. If you are looking to add trajectory and spin to your wedges, the KBS Tour V shaft will deliver.

The Highlands Performance Golf Center, Carrollton Texas

The Highlands Performance Golf Center, Carrollton Texas

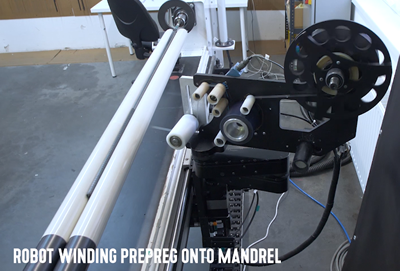

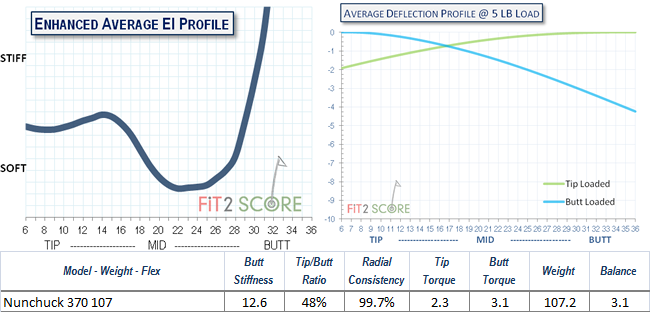

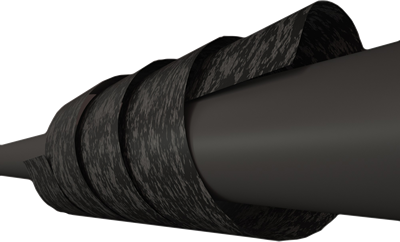

TPT makes their shafts out of carbon fiber ribbon cut from the prepreg sheets they make. The ribbon is wrapped around the shaft mandrel. The result is a seamless shaft with uniform stiffness in all orientations. That was verified in my measurement, Radial Quality, shown below. It is the best in the business.

TPT makes their shafts out of carbon fiber ribbon cut from the prepreg sheets they make. The ribbon is wrapped around the shaft mandrel. The result is a seamless shaft with uniform stiffness in all orientations. That was verified in my measurement, Radial Quality, shown below. It is the best in the business.