True Temper Project X Black Hybrid Shaft

True Temper Project X Blue Hybrid Shaft

By Russ Ryden, A Golf Digest America’s 100 Best Clubfitter

Fit2Score, Dallas Fort Worth, Texas

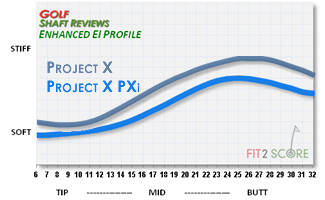

At the time of this review the Project X Black and Blue Hybrid shafts have been on the market for several years. They represent classic hybrid shaft designs seen over and over from different brands. The Project X Black has a quick loss of stiffness tightening around 18″ from the tip and running from there into a long stable tip. This design is easy to tip trim into different loft hybrids, increasing the stiffness for the increased head weight as the lofts get larger. From my experience with similar profiles you will see a mid high flight with enough spin to create a nice drop and stop ball flight.

At the time of this review the Project X Black and Blue Hybrid shafts have been on the market for several years. They represent classic hybrid shaft designs seen over and over from different brands. The Project X Black has a quick loss of stiffness tightening around 18″ from the tip and running from there into a long stable tip. This design is easy to tip trim into different loft hybrids, increasing the stiffness for the increased head weight as the lofts get larger. From my experience with similar profiles you will see a mid high flight with enough spin to create a nice drop and stop ball flight.

To continue reading this section of the review, you must be registered at a higher level membership.

Russ