Nventix Nunchuck Driver, Nunchuck Hybrid, Nunchuck Iron

Nunchuck Driver Shaft

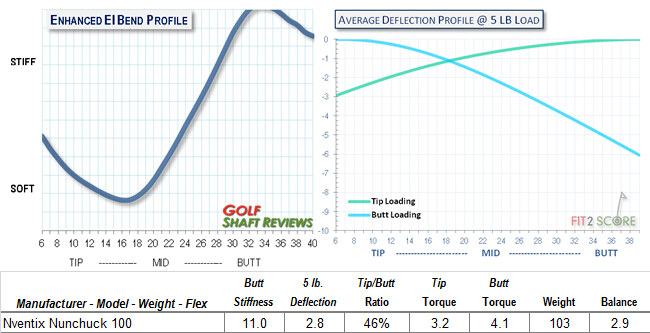

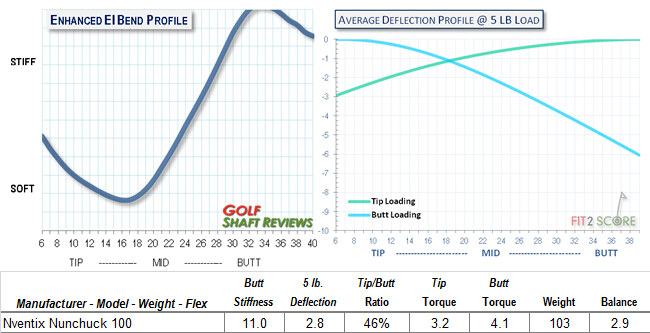

The Nventix folks are Dallas based as am I. The CEO, Mike McCall lives less than a mile from me. I have known about this shaft since its early days. The design idea comes from Bruce Devlin, a nine-time PGA Tour/PGA Senior Tour winner. Create a shaft with a stiff handle and tip, focusing all the flex in the middle of the shaft. An extensive discussion of the science is presented on the Nventix web site with a detailed explanation of the concept in the frequently asked questions tab.

The stiff tip facilitates less shaft related head movement as you approach impact. That is a good thing. A 103 gram driver shaft raises my eyebrows. But, for many, adding a counter weight to a shaft is going to accomplish much the same from a total weight perspective. And I and fellow fitters have put a great many players into counterweights.

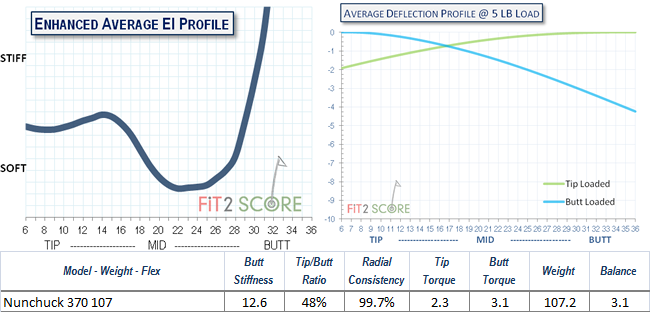

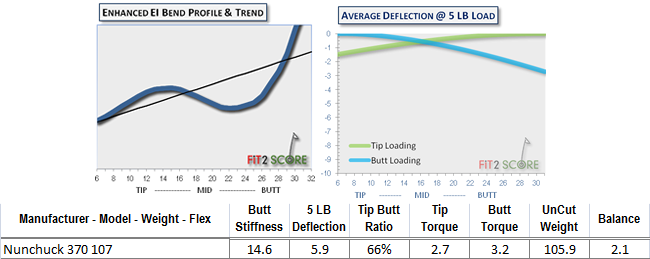

Radial consistency is 99.4%, orientation in rotating hosels is a non issue. Before you look at the profile and wonder how such a severe change in stiffness will even be playable, look at this next image. This is the translation of EI into deflection.

Variations of this EI profile are seen in a few other shafts. Not exactly, but much closer than I had thought. What is rarely seen is the weight in a driver shaft. And that is something you will have to try for yourself. The butt stiffness is off the charts. That illustrates the inherent flaw in using butt stiffness to rate shafts. Feel comes from many factors. The rate and amount of loss of stiffness down the shaft as well as torque combine to produce feel.

It is fairly well known among radar equipped fitters that shaft stiffness reduces dispersion. To the degree that stiffness does not change your swing, it is a good thing. The Nunchuck driver shaft is stiff by all measurements, deflection, load, frequency. It has an EI profile that we are new seeing in a number of iron shaft designs. A rapid loss of stiffness in the middle of the shaft followed by a long stable tip. If you can handle the weight, it is now becoming a popular design.

Nunchuck Hybrid Shaft

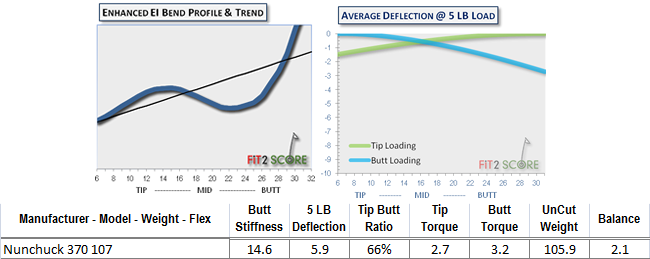

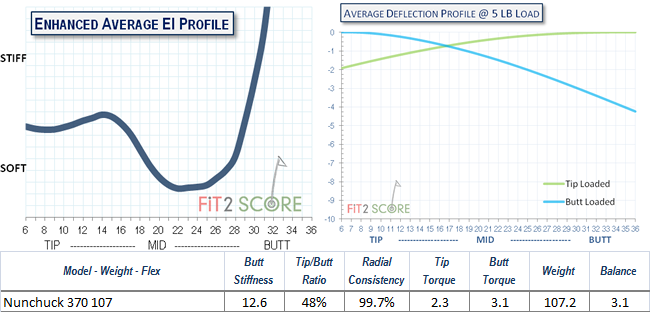

The Nventix Nunchuck Hybrid shaft came along a year to two after the introduction of the driver shaft. The design is similar. The automatically enhanced graphic below does a bit of injustice to the actual design, but is comparable to the rest of the images on this site.

Radial consistency is 99.7%, outstanding, orientation in rotating hosels is a non issue. Once again, remember, EI profiles show the sitffness of the 36 ‘springs’ we measure that constitute a golf shaft. When these springs are interconnected, the deflection profile is smooth. On this shaft, I see a weight range that is without question acceptable in many bags. The stiffness is in the range of many shafts I fit strong players into. The unique design is one of the lowest launch propensities I know of.

Radial consistency is 99.7%, outstanding, orientation in rotating hosels is a non issue. Once again, remember, EI profiles show the sitffness of the 36 ‘springs’ we measure that constitute a golf shaft. When these springs are interconnected, the deflection profile is smooth. On this shaft, I see a weight range that is without question acceptable in many bags. The stiffness is in the range of many shafts I fit strong players into. The unique design is one of the lowest launch propensities I know of.

Nunchuck Iron Shaft

Like all the Nventix shafts, the radial consistency of the iron shaft is exceptional, 98.9%. It is an unusual design with a unique trim pattern. The typical shaft of this style, a single shaft often called parallel blanks get trimmed from the tip, creating increasing stiffness as the shafts get shorter in response to the heads getting heavier. The Nunchuck is a taper tip design, and a single shaft is used to create the set, trimmed from the butt. That is an unusual approach but I have build a few of these on request for some good ball strikers.

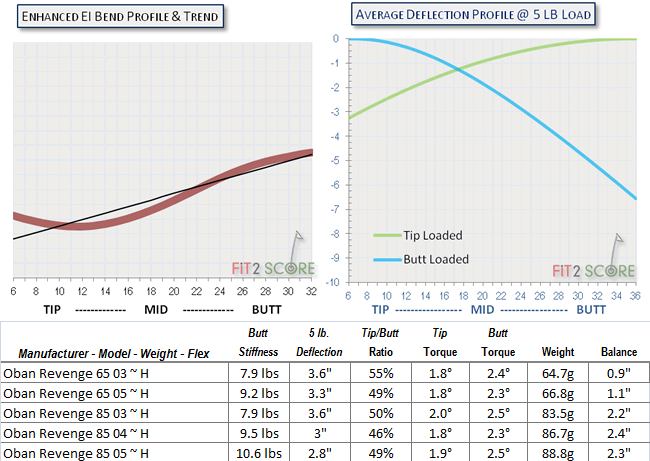

![]() These Revenge hybrid shafts do produce impressive dispersion results in real world testing, especially for shafts in these weight categories. The flight is mid-high to high, but they do not balloon, even in the Texas wind. The use of ultra premium graphite materials ensures a consistent bend profile, better performance and consistent shots. The low torque provides very tight dispersion. The moderately softer tip and butt sections of this shaft provide a responsive feel that never seems boardy.

These Revenge hybrid shafts do produce impressive dispersion results in real world testing, especially for shafts in these weight categories. The flight is mid-high to high, but they do not balloon, even in the Texas wind. The use of ultra premium graphite materials ensures a consistent bend profile, better performance and consistent shots. The low torque provides very tight dispersion. The moderately softer tip and butt sections of this shaft provide a responsive feel that never seems boardy.