Matrix SpeedRulz Driver Shaft

By Russ Ryden & Jim Achenbach

Russ Ryden, Fit2Score, A Dallas Fort Worth Club Fitter & Club Maker

The Golf Center at the Highlands, Carrollton Texas

For more than 20 years, the graphite golf shaft manufacturer known as Matrix has retained something of a cult following among touring professionals and highly skilled amateurs. Many ordinary golfers, though, know more about Matrix the movie than they do Matrix the golf shaft.

But that is changing, thanks in large part to the new Matrix SpeedRulz driver shaft and PGA Tour players Rickie Fowler and Fabian Gomez. In the last 10 months, Fowler has won three tournaments (Players Championship, Scottish Open, Deutsche Bank Championship) and Gomez two (FedEx St. Jude, Sony Open in Hawaii) — all with the SpeedRulz shaft.

To be honest, some of the consumer confusion came from the name of the shaftmaker, which originally was Apache but later was changed to Matrix. K.J. Choi created a buzz in 2004-2005 when he used bright orange Apache shafts on the PGA Tour. Choi later switched back to steel iron shafts, but the Apache/Matrix name was starting to slowly building a following in the graphite shaft universe. Most Tour players, including Choi, Fowler and Gomez, are not paid to use a particular shaft brand. It is simply a matter of individual preference.

Following Choi, the next big assist for Matrix came from TaylorMade, which designated the shaftmaker as one of its primary suppliers.

Now, 23 years after Apache was founded in 1993, Matrix sometimes is cited incorrectly as a new shaftmaker that came out of nowhere. Golf equipment historians know better.

The long-range goal of SpeedRulz is to appeal to amateur golfers of various abilities. To accomplish this goal, three variations of the shaft were devised by chief designer Daniel You. The SpeedRulz A-Type, with weights of 50, 60 and 70 grams, is aimed at golfers with somewhat slower swing speeds. Generally these players would exhibit a swing profile that appears smooth and balanced. B-Type is backweighted — or counter balanced — for a golfer who prefers a longer club or a heavier head. It is slightly firmer in the butt and mid sections and a little softer in the tip. Available in weights of 60, 70 and 80 grams. The low-spinning, low-launching C-Type, used by Fowler and Gomez, is firmer in the tip and slightly softer in the handle. The two weights are 60 and 70 grams. The hallmark of these shafts, according to Matrix president Chris Elson: “All three feel stable, but not boardy. Golfers can go after it without the shaft feeling loose or soft.” Each of the three is widely available for $275 at retail.

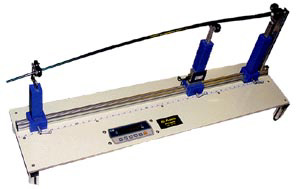

Matrix has always focused on shaft technology. At Apache golf a unique shaft measuring instrument, the MultiMatch was created and sold to club fitters. It was long regarded as one of the best instruments available to the club making community for understand golf shafts. It was never that popular because of the cost, but those club fitters that own them still use them. It was revised a few years ago, but once again the expense is outside the budget of most club fitters.

Matrix has always focused on shaft technology. At Apache golf a unique shaft measuring instrument, the MultiMatch was created and sold to club fitters. It was long regarded as one of the best instruments available to the club making community for understand golf shafts. It was never that popular because of the cost, but those club fitters that own them still use them. It was revised a few years ago, but once again the expense is outside the budget of most club fitters.

Matrix is one of a very few golf shaft companies that make their own prepreg. That gives them the ability to create unique properties. They consistently produce round shafts, a property they call “Circumferential Flexural Integrity”, CFI. For me, consistency around the shaft is one of those go / no go properties. If a shaft is not round, no amount of ‘spining’, ‘puring’ or alignment is going to make it better. If it is round, none of these things matter. The SpeedRulz are round, the average hard to soft side difference was 99.5% with a 0.4% standard deviation. That’s as good as it gets.

The three designs, A, B and C are available in two color schemes, Black and Red. There is no difference between the two paint colors other than color. Here are the numbers and profiles

To continue reading this section of the review, you must be registered at a higher level membership.

Russ

The design targets of the SpeedRulz are eloquently described in the video by Chris Elson, president of Matrix Golf Shafts.

Matrix is making its own Prepreg. In southern China, Matrix has built an entire manufacturing headquarters and campus from the ground up. The new facility allows Matrix to make not only shafts, but also prepreg. What is prepreg? It is the material — containing carbon fibers impregnated with resin — used to make graphite shafts. It is manufactured in sheet form and is molded, using a variety of patterns, into graphite shafts.

The new plant is the result of a strategic alliance between Matrix and Toray, the largest manufacturer of prepreg in the world. Matrix, according to Elson, is expecting to have access to unique fiber types for future graphite shafts.

The technical discussion, measurements and testing results are available only to registered readers